QMol

This £7M, five-year project, has been funded by the EPSRC and is entitled “Quantum engineering of energy-efficient molecular materials (QMol)”. It is led by Professor Colin Lambert from Lancaster University with a world leading team of scientists to develop radically new organic materials for everything from smart textiles to self-powered patches for healthcare. See our introductory animation at Molecular Electronics.

Goals

QMol will realise a new generation of switchable organic/organometallic compounds, with the potential to fulfil societal needs for flexible energy harvesting materials, low-power neuromorphic computing, smart textiles and self-powered patches for healthcare. The possibility of creating these exciting materials derives from a series of world firsts by the investigators which demonstrate that advantageous room-temperature quantum interference effects can be scaled up from single molecules to self-assembled monolayers by using new strategies for controlling molecular conformation and energy levels with new methods of molecular assembly which can then be deployed in printed scalable architectures.

The Goals lead to the Themes listed below

Organic Thermoelectrics

Thermoelectric molecular films will convert low-grade waste heat into electrical energy whilst cooling the system. Unlike existing thermoelectric generators, the heat gradient lies perpendicular to the surface, which is ideal for integrating into devices. As predicted by Famili et al., the thermal conductivity of molecules can be modified by incorporating pendant groups to manage the flow of phonons. These new materials will be characterised at the single-molecule level, in monolayers and in multilayer films.

Smart Textiles with Thermal Management

Multi-layers of thermally switchable molecules on planar versions of polyester, lyocell, polyurethane and cellulose will be benchmarked, informing the coating of polymeric fibres. Large area printed films of switchable molecules will allow us to estimate the collective thermal behaviour of the switching layer as a function of thickness, roughness, bending, extension/compression, permeability. Optimal coating procedures (inkjet, spray/dip coating) will be identified for the creation of the core-shell thermally switching fibres.

Switchable Films

Asymmetric molecules will be designed with inhomogeneous charge distributions, which allow them to internally switch between two or more resistive states using an applied source-drain voltage. This ‘memristive’ behaviour will be assessed at the single-molecule level and in self-assembled monolayers. Molecules designed to be switched by an applied thermal gradient, pressure and light will also be synthesised and characterised.

Cross-Plane Memristive Devices

Memristive switches will be first investigated in a vertical configuration on rigid surfaces compatible with existing computing and flexible substrates using asymmetric molecules deposited by conventional solution processes or lithography and by spray coating in a multi-layer thin-film configuration. Interconnected memristor matrices will be developed also by inkjet printing the thermal switching films in multiple parallel arrays with resolutions of 50-100 microns. Gold, copper and graphene electrodes will be tested and utilised.

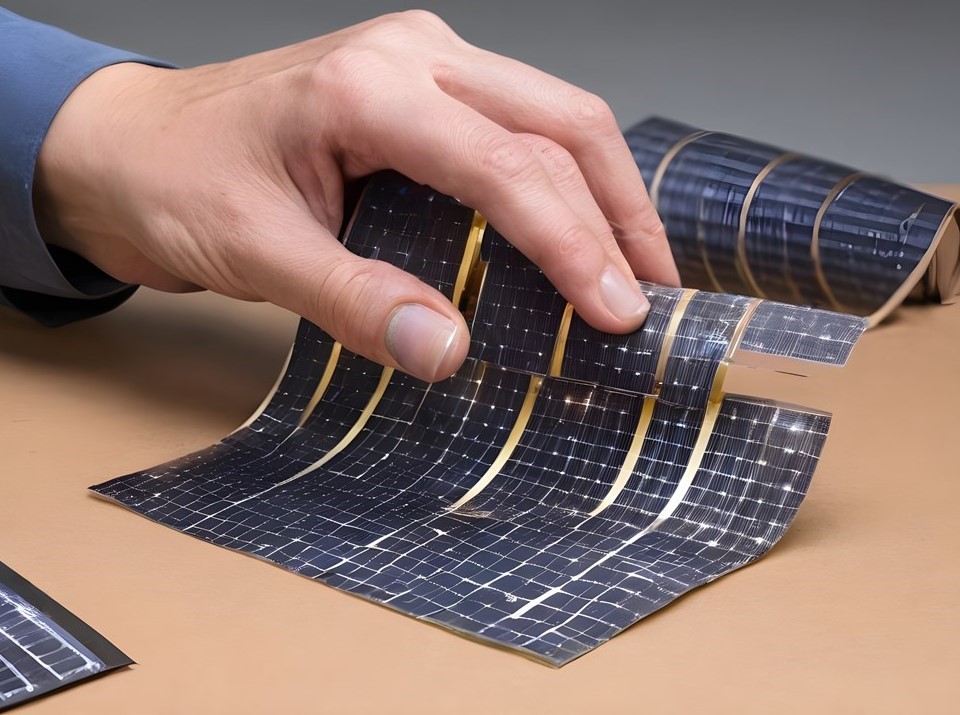

Flexible multi-layer Thermoelectric Generators and self-powered patches for Healthcare

Building up from single-layer to multilayer p-type and n-type thermoelectric generators (TEGs) based initially on gold bottom electrodes, molecules and graphene top electrodes, these will be fabricated using controlled lithographic techniques, gold evaporation, solution processed molecular layers and graphene transfer. Inkjet printing drop-on-demand and spray coating will be used to assemble uniform thin films of TEGs. Multi-layer configurations will then be developed via layer-by-layer deposition by drop-on-demand inkjet printing, screen printing or spray coating. Optimised TEG layouts will be integrated on wearable patches as local energy sources for distributed sensor networks. Inkjet printing will enable versatile patterning of the thermoelectric films on textile and flexible substrates in amalgamation with the sensing design. Applications will include self-powered electrocardiogram devices able to sense pH and temperature changes, heat management patches able to dynamically heat or cool local regions of the body, by switching the thermal properties of the printed/coated films and an elastoplaster, which generates an electric field across a wound to promote healing.